This is not officially published by PCB producer, and I don't have any promotional relationship with PCB seller which is KPRepublic. I write this to make as a note for me and for fellow hobbyists out there if they are stuck with programming steps on XD60 rev3 PCB.

It was a long time ago since I was posted on my blog, been busy with work and hobby lately. I don't know how I can get into this hobby, but I just read it somewhere and see some cool keyboards out there with some customization and nice keycaps to make a "thock" sound which is really relaxing and I decided to find out about it. Here I am now with my first custom board XD60 rev3 and supported many layouts like arrow cluster on 60% keyboards.

So the first question appear on my head was how to flash this little beast? This PCB supported by QMK firmware and that firmware so powerful with many functions could be added into the keyboards. First of all, go to docs.qmk.fm

You should see there is instruction on there to build the QMK environment.

From msys2 website you have to choose the installer based on your PC architecture.

You can read from there for a better explanation to install the application. After all installation process succeeded, you can open the MSYS2 MinGW 64-bit application and it should look like this.

Run the application and Navigate to your QMK repository. For example, if it's in the root of your c drive: "cd /c/qmk_firmware"

It's pretty self-explanation from QMK website. Next step was Run "util/qmk_install.sh" from the command line and follow the prompts. All command should be run without quotes.

If all of this step was already done, you would be ready to compile your keymap on the keyboard. I assume if you are Windows user you could find qmk_firmware files in C:\msys64\home\(your windows username)\qmk_firmware

The first you need to do is select keyboards folder and chooses xd60 folder.

Select it and then you could see three folders there and select keymaps folder. Make a new folder with your name or whatever as you wish the folder's name. As an example, I make folder rudi since it is my name.

Now copy keymap.c on default keymaps folder and paste it into rudi folder. You can change the keymaps later. This step just to make sure QMK build environment work as expected.

Type "make xd60/rev3:rudi" on your MSYS2 application like this. Make sure which version your board it is, if it is rev2 change it accordingly.

If all OK sign has appeared, you can find hex files already made in your qmk_firmware folder. Find file with "xd60_rev3_rudi.hex" name. Now you are ready to flash the keyboard. Make a change to keymaps as your wish on rudi keymaps folder which we make before and compile it again if you are not satisfied with keymaps layout.

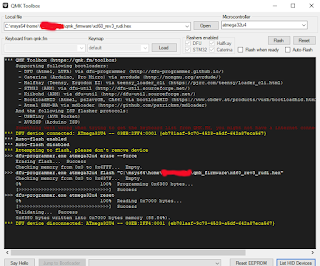

After we have gone so far, now we need to download the latest release QMK toolbox. After the download finished, open it and select your hex files was made before.

I blurred my Windows username just for privacy. Tick Auto-Flash and connect your PCB to your computer and press the button on the back of the PCB. It should be connected and if not try to install driver zadig.exe

If everything was done correctly it would auto flash the moment you press the button from the back of the PCB. From the above picture, you could see it is already flashed and your XD60 ready to type on! Enjoy your DIY keyboard from now!

So the first question appear on my head was how to flash this little beast? This PCB supported by QMK firmware and that firmware so powerful with many functions could be added into the keyboards. First of all, go to docs.qmk.fm

You should see there is instruction on there to build the QMK environment.

You can read from there for a better explanation to install the application. After all installation process succeeded, you can open the MSYS2 MinGW 64-bit application and it should look like this.

Run the application and Navigate to your QMK repository. For example, if it's in the root of your c drive: "cd /c/qmk_firmware"

It's pretty self-explanation from QMK website. Next step was Run "util/qmk_install.sh" from the command line and follow the prompts. All command should be run without quotes.

If all of this step was already done, you would be ready to compile your keymap on the keyboard. I assume if you are Windows user you could find qmk_firmware files in C:\msys64\home\(your windows username)\qmk_firmware

The first you need to do is select keyboards folder and chooses xd60 folder.

Select it and then you could see three folders there and select keymaps folder. Make a new folder with your name or whatever as you wish the folder's name. As an example, I make folder rudi since it is my name.

Now copy keymap.c on default keymaps folder and paste it into rudi folder. You can change the keymaps later. This step just to make sure QMK build environment work as expected.

Type "make xd60/rev3:rudi" on your MSYS2 application like this. Make sure which version your board it is, if it is rev2 change it accordingly.

If all OK sign has appeared, you can find hex files already made in your qmk_firmware folder. Find file with "xd60_rev3_rudi.hex" name. Now you are ready to flash the keyboard. Make a change to keymaps as your wish on rudi keymaps folder which we make before and compile it again if you are not satisfied with keymaps layout.

After we have gone so far, now we need to download the latest release QMK toolbox. After the download finished, open it and select your hex files was made before.

I blurred my Windows username just for privacy. Tick Auto-Flash and connect your PCB to your computer and press the button on the back of the PCB. It should be connected and if not try to install driver zadig.exe

If everything was done correctly it would auto flash the moment you press the button from the back of the PCB. From the above picture, you could see it is already flashed and your XD60 ready to type on! Enjoy your DIY keyboard from now!

This is not officially published by PCB producer, and I don't have any promotional relationship with PCB seller which is KPRepublic. I write this to make as a note for me and for fellow hobbyists out there if they are stuck with programming steps on XD60 rev3 PCB.

It was a long time ago since I was posted on my blog, been busy with work and hobby lately. I don't know how I can get into this hobby, but I just read it somewhere and see some cool keyboards out there with some customization and nice keycaps to make a "thock" sound which is really relaxing and I decided to find out about it. Here I am now with my first custom board XD60 rev3 and supported many layouts like arrow cluster on 60% keyboards.

So the first question appear on my head was how to flash this little beast? This PCB supported by QMK firmware and that firmware so powerful with many functions could be added into the keyboards. First of all, go to docs.qmk.fm

You should see there is instruction on there to build the QMK environment.

From msys2 website you have to choose the installer based on your PC architecture.

You can read from there for a better explanation to install the application. After all installation process succeeded, you can open the MSYS2 MinGW 64-bit application and it should look like this.

Run the application and Navigate to your QMK repository. For example, if it's in the root of your c drive: "cd /c/qmk_firmware"

It's pretty self-explanation from QMK website. Next step was Run "util/qmk_install.sh" from the command line and follow the prompts. All command should be run without quotes.

If all of this step was already done, you would be ready to compile your keymap on the keyboard. I assume if you are Windows user you could find qmk_firmware files in C:\msys64\home\(your windows username)\qmk_firmware

The first you need to do is select keyboards folder and chooses xd60 folder.

Select it and then you could see three folders there and select keymaps folder. Make a new folder with your name or whatever as you wish the folder's name. As an example, I make folder rudi since it is my name.

Now copy keymap.c on default keymaps folder and paste it into rudi folder. You can change the keymaps later. This step just to make sure QMK build environment work as expected.

Type "make xd60/rev3:rudi" on your MSYS2 application like this. Make sure which version your board it is, if it is rev2 change it accordingly.

If all OK sign has appeared, you can find hex files already made in your qmk_firmware folder. Find file with "xd60_rev3_rudi.hex" name. Now you are ready to flash the keyboard. Make a change to keymaps as your wish on rudi keymaps folder which we make before and compile it again if you are not satisfied with keymaps layout.

After we have gone so far, now we need to download the latest release QMK toolbox. After the download finished, open it and select your hex files was made before.

I blurred my Windows username just for privacy. Tick Auto-Flash and connect your PCB to your computer and press the button on the back of the PCB. It should be connected and if not try to install driver zadig.exe

If everything was done correctly it would auto flash the moment you press the button from the back of the PCB. From the above picture, you could see it is already flashed and your XD60 ready to type on! Enjoy your DIY keyboard from now!

So the first question appear on my head was how to flash this little beast? This PCB supported by QMK firmware and that firmware so powerful with many functions could be added into the keyboards. First of all, go to docs.qmk.fm

You should see there is instruction on there to build the QMK environment.

You can read from there for a better explanation to install the application. After all installation process succeeded, you can open the MSYS2 MinGW 64-bit application and it should look like this.

Run the application and Navigate to your QMK repository. For example, if it's in the root of your c drive: "cd /c/qmk_firmware"

It's pretty self-explanation from QMK website. Next step was Run "util/qmk_install.sh" from the command line and follow the prompts. All command should be run without quotes.

If all of this step was already done, you would be ready to compile your keymap on the keyboard. I assume if you are Windows user you could find qmk_firmware files in C:\msys64\home\(your windows username)\qmk_firmware

The first you need to do is select keyboards folder and chooses xd60 folder.

Select it and then you could see three folders there and select keymaps folder. Make a new folder with your name or whatever as you wish the folder's name. As an example, I make folder rudi since it is my name.

Now copy keymap.c on default keymaps folder and paste it into rudi folder. You can change the keymaps later. This step just to make sure QMK build environment work as expected.

Type "make xd60/rev3:rudi" on your MSYS2 application like this. Make sure which version your board it is, if it is rev2 change it accordingly.

If all OK sign has appeared, you can find hex files already made in your qmk_firmware folder. Find file with "xd60_rev3_rudi.hex" name. Now you are ready to flash the keyboard. Make a change to keymaps as your wish on rudi keymaps folder which we make before and compile it again if you are not satisfied with keymaps layout.

After we have gone so far, now we need to download the latest release QMK toolbox. After the download finished, open it and select your hex files was made before.

I blurred my Windows username just for privacy. Tick Auto-Flash and connect your PCB to your computer and press the button on the back of the PCB. It should be connected and if not try to install driver zadig.exe

If everything was done correctly it would auto flash the moment you press the button from the back of the PCB. From the above picture, you could see it is already flashed and your XD60 ready to type on! Enjoy your DIY keyboard from now!

Here is LC Meter that you can build yourself, you can find the schematic, board design also included and description for building from Phil Rice VK3BHR

Another site sells this LC Meter and looks neat. It would help to identify the components easily especially for the radio amateur. Try to get it one.

" This is one of the most accurate and simplest LC inductance/capacitance Meters that one can find, yet one that you can easily build yourself. This LC Meter allows to measure incredibly small inductances starting from 10nH to 1000nH, 1uH to 1000uH, 1mH to 100mH and capacitance from 0.1pF up to 900nF. LC Meter's circuit uses an auto ranging system so that way you do not need to spend time selecting ranges manually. Another neat function is the reset switch that will reset the initial inductance/capacitance, making sure that the final readings of the LC Meter are as accurate as possible."

Link : http://electronics-diy.com/lc_meter.php

Another site sells this LC Meter and looks neat. It would help to identify the components easily especially for the radio amateur. Try to get it one.

" This is one of the most accurate and simplest LC inductance/capacitance Meters that one can find, yet one that you can easily build yourself. This LC Meter allows to measure incredibly small inductances starting from 10nH to 1000nH, 1uH to 1000uH, 1mH to 100mH and capacitance from 0.1pF up to 900nF. LC Meter's circuit uses an auto ranging system so that way you do not need to spend time selecting ranges manually. Another neat function is the reset switch that will reset the initial inductance/capacitance, making sure that the final readings of the LC Meter are as accurate as possible."

Link : http://electronics-diy.com/lc_meter.php

Here is LC Meter that you can build yourself, you can find the schematic, board design also included and description for building from Phil Rice VK3BHR

Another site sells this LC Meter and looks neat. It would help to identify the components easily especially for the radio amateur. Try to get it one.

" This is one of the most accurate and simplest LC inductance/capacitance Meters that one can find, yet one that you can easily build yourself. This LC Meter allows to measure incredibly small inductances starting from 10nH to 1000nH, 1uH to 1000uH, 1mH to 100mH and capacitance from 0.1pF up to 900nF. LC Meter's circuit uses an auto ranging system so that way you do not need to spend time selecting ranges manually. Another neat function is the reset switch that will reset the initial inductance/capacitance, making sure that the final readings of the LC Meter are as accurate as possible."

Link : http://electronics-diy.com/lc_meter.php

Another site sells this LC Meter and looks neat. It would help to identify the components easily especially for the radio amateur. Try to get it one.

" This is one of the most accurate and simplest LC inductance/capacitance Meters that one can find, yet one that you can easily build yourself. This LC Meter allows to measure incredibly small inductances starting from 10nH to 1000nH, 1uH to 1000uH, 1mH to 100mH and capacitance from 0.1pF up to 900nF. LC Meter's circuit uses an auto ranging system so that way you do not need to spend time selecting ranges manually. Another neat function is the reset switch that will reset the initial inductance/capacitance, making sure that the final readings of the LC Meter are as accurate as possible."

Link : http://electronics-diy.com/lc_meter.php

LCD Flat panel TV troubleshooting guide by Bud Martin

Troubleshooting LCD flat panel TV.

This is the basic guide that can be applied to most LCD flat panel TV.

First, try unplugging it from the outlet for about an hour to see if the TV will reset itself since the minute the TV is plugged into the wall, the power supply and processor will be running 24/7 and the EPROM can get corrupted by spikes and surges. Try using good quality surge suppressor to see if it will help if it happen often.

Look for burnt brown hot spots on the circuit boards, capacitors with leaking/bulging top or seals. Loose wires and connectors. Blown fuses.

Notes: We are dealing with high voltage that can kill you! so if you are not sure what you are doing, please have it fixed by the pro that has proper tools and safety equipment. Try to use GFI

outlet and isolation transformer when work around the TV set and DO NOT DEFEAT THE GROUND

PIN OF THE OUTLET/POWER CORD.

Background on LCD TV: http://en.wikipedia.org/wiki/LCD_television

1) The power supply module (There are 4 regulated output voltages:- Standby 5vdc, switched

5vdc, 12~16vdc, and 24vdc).

The power supply converts the 120/230vac 50/60Hz into DC, then the high frequency (50~100kHz)

switching circuits convert it back to AC but at high frequency which allows the power supply to use

smaller and much lighter weight transformers (Ferrite core instead of the heavy iron core), then this high

frequency AC voltage is fed to the rectifier Diodes to get the DC output and filtered by DC filter capacitors

that must have low ESR (Equivalent Series Resistance) if general purpose electrolytic caps are used, they

will fail within a year or less due to high ESR.

The power supply has Standby 5vdc (5VSB, this is a MUST have before anything else will work,

when this voltage is not present, there will be no any indicator light on the front panel) which is

always on the minute the TV is plugged into the AC outlet, so it is on 24/7 and that is why the power

supply will fail even though you may use the TV not very often. It will see all the voltage spikes and

surges 24/7.

This 5vdc is used to power the Processor and the Infrared remote receiver module which will be waiting

for the command from the remote control or from the power switch, when the Power on command is

received, the Processor will send the turn-on signal (3.3~5vdc) to the power supply module (PSON pin) to the switch on the main 5vdc for the rest of the logic and Tuner circuits, 12~16vdc for the sound

amplifiers (mostly Class D amplifier for efficiency and small size) and for the T-CON board (interface

board between the LCD panel and the Logic board), and 24vdc for the Backlights inverter board (if there is no 24vdc then no backlight).

Common failures:

Blown main AC fuse due to shorted out Diodes, transistors.

Bad capacitors leaking or bulging tops: http://en.wikipedia.org/wiki/Capacitor_plague

Shorted Diodes, transistors in the DC output side.

Testing the power supply output with dummy load:

24vdc testing: Disconnect the wires that go to the inverter board first. You can use two #1157 (using

both Lo & Hi filaments by paralleling them at the base) car light bulbs connected in series so they can

handle the 24vdc, this will put light load (about 70w) on the 24vdc output, the voltage out should be

steady at 24vdc (+/-2v), if not, the power supply has regulation problem.

12vdc testing: disconnect the 12vdc TV load from the power supply board and attach one #1157 (using just the Hi filament), the 12vdc output should stay at 12v (+/-1v), if not, the power supply has a regulation problem.

You should see the lamps go on when the TV power switch is ON and go OFF when the TV is powered

OFF.

2) Main Logic board (It has Processor, Tuner, Sound Processor, Sources selector, Power

amplifiers for speakers, interface port to the T-CON board for pictures).

This logic board sends out the turn on signals (3.3~5vdc) to turn on the rest of the Power supply module

(Switched main 5vdc, 12~16vdc, and 24vdc), Inverter backlight ON (if no backlight on command then

there are no backlights),

Logic board supplies 5 or 12vdc to T-CON board B+ pin through switched transistor if T-CON board does

not get the voltage from the logic board, you will get a white/gray glowing screen without pictures.

Backlights Dimming (PWM) control signal.

3) Back lights Inverter board. Its job is to provide the drive voltage for the CCFL (Cold Cathode

Fluorescent Lamp) to give white light for the screen.

This board is fed by the switched 24vdc (VBL) from the power supply module, it also gets the Back lights

on (BL on) control signal and the Dimming (Dim/PWM/) signal from the logic board. So for it to work, it needs 24vdc and the BL_ON signal.

Common failures:

Blown surface mounted fuses due to shorted transistors/ICs, Transformers.

Bad capacitors.

4) The T-CON (Timing Control or LCD controller) board (on the LCD panel assembly). It transfers the universal image signal of TTL and LVDS signal to specific TFT (Thin Film Transistor) LCD.

This is the interface board that talks to the Logic board and the LCD panel to produce pictures on the screen. White/gray glowing screen when it fails or not getting the voltage from the logic board (the 5 or 12vdc is supplied by switched transistor on the logic board). Notes: T-CON board is mounted under the metal cover shield.

Common failures:

Scrambled pictures, Lines, multiple pictures, color smears/blotches, rolling pictures after warm up.

Blown surface-mounted fuse.

No pictures, very dark screen almost like there is no backlights.

DIY Blue Ring Tester

5) LCD panel assembly to display pictures. The LCD pixels will block or unblock the backlights from the back of the panel to the front of the panel. This is the most expensive part of the TV, it will be more than the TV is worth.

As you can see, you must have all the above Voltages and signals for the TV to work properly. This may help you narrowing down the bad modules instead of buying the wrong module just to find out later that it did not solve the problem. Hope this will help you out.

Sound problem:

Let verify first to narrow down to where the problem can be. First, check the on-screen sound set up menu to make sure the speakers are not set to OFF. If the setting is OK, then attach the powered PC

speakers to the Audio Line out RCA jacks to see if you can get the sound there, if you do, then the

problem can be in the power amp circuits, if you do not get the sound at RCA jacks, then the problem can be in the sound processor circuit.

To get the sound repair, it can be from $150 and up, so if you can put up with using the good set of Powered PC speakers which actually give better sound than the tiny speakers inside the TV, I would keep using it that way, you may want to find out if the on-screen sound setup will allow you to set the audio line out to be VARIABLE which means the sound output feeding the PC speakers can be varied using the TV remote control, then all you have to do is to set the PC volume to about half way up and set the TV volume to whatever you want.

Troubleshooting LCD flat panel TV.

This is the basic guide that can be applied to most LCD flat panel TV.

First, try unplugging it from the outlet for about an hour to see if the TV will reset itself since the minute the TV is plugged into the wall, the power supply and processor will be running 24/7 and the EPROM can get corrupted by spikes and surges. Try using good quality surge suppressor to see if it will help if it happen often.

Look for burnt brown hot spots on the circuit boards, capacitors with leaking/bulging top or seals. Loose wires and connectors. Blown fuses.

Notes: We are dealing with high voltage that can kill you! so if you are not sure what you are doing, please have it fixed by the pro that has proper tools and safety equipment. Try to use GFI

outlet and isolation transformer when work around the TV set and DO NOT DEFEAT THE GROUND

PIN OF THE OUTLET/POWER CORD.

Background on LCD TV: http://en.wikipedia.org/wiki/LCD_television

1) The power supply module (There are 4 regulated output voltages:- Standby 5vdc, switched

5vdc, 12~16vdc, and 24vdc).

The power supply converts the 120/230vac 50/60Hz into DC, then the high frequency (50~100kHz)

switching circuits convert it back to AC but at high frequency which allows the power supply to use

smaller and much lighter weight transformers (Ferrite core instead of the heavy iron core), then this high

frequency AC voltage is fed to the rectifier Diodes to get the DC output and filtered by DC filter capacitors

that must have low ESR (Equivalent Series Resistance) if general purpose electrolytic caps are used, they

will fail within a year or less due to high ESR.

The power supply has Standby 5vdc (5VSB, this is a MUST have before anything else will work,

when this voltage is not present, there will be no any indicator light on the front panel) which is

always on the minute the TV is plugged into the AC outlet, so it is on 24/7 and that is why the power

supply will fail even though you may use the TV not very often. It will see all the voltage spikes and

surges 24/7.

This 5vdc is used to power the Processor and the Infrared remote receiver module which will be waiting

for the command from the remote control or from the power switch, when the Power on command is

received, the Processor will send the turn-on signal (3.3~5vdc) to the power supply module (PSON pin) to the switch on the main 5vdc for the rest of the logic and Tuner circuits, 12~16vdc for the sound

amplifiers (mostly Class D amplifier for efficiency and small size) and for the T-CON board (interface

board between the LCD panel and the Logic board), and 24vdc for the Backlights inverter board (if there is no 24vdc then no backlight).

Common failures:

Blown main AC fuse due to shorted out Diodes, transistors.

Bad capacitors leaking or bulging tops: http://en.wikipedia.org/wiki/Capacitor_plague

Shorted Diodes, transistors in the DC output side.

Testing the power supply output with dummy load:

24vdc testing: Disconnect the wires that go to the inverter board first. You can use two #1157 (using

both Lo & Hi filaments by paralleling them at the base) car light bulbs connected in series so they can

handle the 24vdc, this will put light load (about 70w) on the 24vdc output, the voltage out should be

steady at 24vdc (+/-2v), if not, the power supply has regulation problem.

12vdc testing: disconnect the 12vdc TV load from the power supply board and attach one #1157 (using just the Hi filament), the 12vdc output should stay at 12v (+/-1v), if not, the power supply has a regulation problem.

You should see the lamps go on when the TV power switch is ON and go OFF when the TV is powered

OFF.

2) Main Logic board (It has Processor, Tuner, Sound Processor, Sources selector, Power

amplifiers for speakers, interface port to the T-CON board for pictures).

This logic board sends out the turn on signals (3.3~5vdc) to turn on the rest of the Power supply module

(Switched main 5vdc, 12~16vdc, and 24vdc), Inverter backlight ON (if no backlight on command then

there are no backlights),

Logic board supplies 5 or 12vdc to T-CON board B+ pin through switched transistor if T-CON board does

not get the voltage from the logic board, you will get a white/gray glowing screen without pictures.

Backlights Dimming (PWM) control signal.

3) Back lights Inverter board. Its job is to provide the drive voltage for the CCFL (Cold Cathode

Fluorescent Lamp) to give white light for the screen.

This board is fed by the switched 24vdc (VBL) from the power supply module, it also gets the Back lights

on (BL on) control signal and the Dimming (Dim/PWM/) signal from the logic board. So for it to work, it needs 24vdc and the BL_ON signal.

Common failures:

Blown surface mounted fuses due to shorted transistors/ICs, Transformers.

Bad capacitors.

4) The T-CON (Timing Control or LCD controller) board (on the LCD panel assembly). It transfers the universal image signal of TTL and LVDS signal to specific TFT (Thin Film Transistor) LCD.

This is the interface board that talks to the Logic board and the LCD panel to produce pictures on the screen. White/gray glowing screen when it fails or not getting the voltage from the logic board (the 5 or 12vdc is supplied by switched transistor on the logic board). Notes: T-CON board is mounted under the metal cover shield.

Common failures:

Scrambled pictures, Lines, multiple pictures, color smears/blotches, rolling pictures after warm up.

Blown surface-mounted fuse.

No pictures, very dark screen almost like there is no backlights.

DIY Blue Ring Tester

5) LCD panel assembly to display pictures. The LCD pixels will block or unblock the backlights from the back of the panel to the front of the panel. This is the most expensive part of the TV, it will be more than the TV is worth.

As you can see, you must have all the above Voltages and signals for the TV to work properly. This may help you narrowing down the bad modules instead of buying the wrong module just to find out later that it did not solve the problem. Hope this will help you out.

Sound problem:

Let verify first to narrow down to where the problem can be. First, check the on-screen sound set up menu to make sure the speakers are not set to OFF. If the setting is OK, then attach the powered PC

speakers to the Audio Line out RCA jacks to see if you can get the sound there, if you do, then the

problem can be in the power amp circuits, if you do not get the sound at RCA jacks, then the problem can be in the sound processor circuit.

To get the sound repair, it can be from $150 and up, so if you can put up with using the good set of Powered PC speakers which actually give better sound than the tiny speakers inside the TV, I would keep using it that way, you may want to find out if the on-screen sound setup will allow you to set the audio line out to be VARIABLE which means the sound output feeding the PC speakers can be varied using the TV remote control, then all you have to do is to set the PC volume to about half way up and set the TV volume to whatever you want.

LCD Flat panel TV troubleshooting guide by Bud Martin

Troubleshooting LCD flat panel TV.

This is the basic guide that can be applied to most LCD flat panel TV.

First, try unplugging it from the outlet for about an hour to see if the TV will reset itself since the minute the TV is plugged into the wall, the power supply and processor will be running 24/7 and the EPROM can get corrupted by spikes and surges. Try using good quality surge suppressor to see if it will help if it happen often.

Look for burnt brown hot spots on the circuit boards, capacitors with leaking/bulging top or seals. Loose wires and connectors. Blown fuses.

Notes: We are dealing with high voltage that can kill you! so if you are not sure what you are doing, please have it fixed by the pro that has proper tools and safety equipment. Try to use GFI

outlet and isolation transformer when work around the TV set and DO NOT DEFEAT THE GROUND

PIN OF THE OUTLET/POWER CORD.

Background on LCD TV: http://en.wikipedia.org/wiki/LCD_television

1) The power supply module (There are 4 regulated output voltages:- Standby 5vdc, switched

5vdc, 12~16vdc, and 24vdc).

The power supply converts the 120/230vac 50/60Hz into DC, then the high frequency (50~100kHz)

switching circuits convert it back to AC but at high frequency which allows the power supply to use

smaller and much lighter weight transformers (Ferrite core instead of the heavy iron core), then this high

frequency AC voltage is fed to the rectifier Diodes to get the DC output and filtered by DC filter capacitors

that must have low ESR (Equivalent Series Resistance) if general purpose electrolytic caps are used, they

will fail within a year or less due to high ESR.

The power supply has Standby 5vdc (5VSB, this is a MUST have before anything else will work,

when this voltage is not present, there will be no any indicator light on the front panel) which is

always on the minute the TV is plugged into the AC outlet, so it is on 24/7 and that is why the power

supply will fail even though you may use the TV not very often. It will see all the voltage spikes and

surges 24/7.

This 5vdc is used to power the Processor and the Infrared remote receiver module which will be waiting

for the command from the remote control or from the power switch, when the Power on command is

received, the Processor will send the turn-on signal (3.3~5vdc) to the power supply module (PSON pin) to the switch on the main 5vdc for the rest of the logic and Tuner circuits, 12~16vdc for the sound

amplifiers (mostly Class D amplifier for efficiency and small size) and for the T-CON board (interface

board between the LCD panel and the Logic board), and 24vdc for the Backlights inverter board (if there is no 24vdc then no backlight).

Common failures:

Blown main AC fuse due to shorted out Diodes, transistors.

Bad capacitors leaking or bulging tops: http://en.wikipedia.org/wiki/Capacitor_plague

Shorted Diodes, transistors in the DC output side.

Testing the power supply output with dummy load:

24vdc testing: Disconnect the wires that go to the inverter board first. You can use two #1157 (using

both Lo & Hi filaments by paralleling them at the base) car light bulbs connected in series so they can

handle the 24vdc, this will put light load (about 70w) on the 24vdc output, the voltage out should be

steady at 24vdc (+/-2v), if not, the power supply has regulation problem.

12vdc testing: disconnect the 12vdc TV load from the power supply board and attach one #1157 (using just the Hi filament), the 12vdc output should stay at 12v (+/-1v), if not, the power supply has a regulation problem.

You should see the lamps go on when the TV power switch is ON and go OFF when the TV is powered

OFF.

2) Main Logic board (It has Processor, Tuner, Sound Processor, Sources selector, Power

amplifiers for speakers, interface port to the T-CON board for pictures).

This logic board sends out the turn on signals (3.3~5vdc) to turn on the rest of the Power supply module

(Switched main 5vdc, 12~16vdc, and 24vdc), Inverter backlight ON (if no backlight on command then

there are no backlights),

Logic board supplies 5 or 12vdc to T-CON board B+ pin through switched transistor if T-CON board does

not get the voltage from the logic board, you will get a white/gray glowing screen without pictures.

Backlights Dimming (PWM) control signal.

3) Back lights Inverter board. Its job is to provide the drive voltage for the CCFL (Cold Cathode

Fluorescent Lamp) to give white light for the screen.

This board is fed by the switched 24vdc (VBL) from the power supply module, it also gets the Back lights

on (BL on) control signal and the Dimming (Dim/PWM/) signal from the logic board. So for it to work, it needs 24vdc and the BL_ON signal.

Common failures:

Blown surface mounted fuses due to shorted transistors/ICs, Transformers.

Bad capacitors.

4) The T-CON (Timing Control or LCD controller) board (on the LCD panel assembly). It transfers the universal image signal of TTL and LVDS signal to specific TFT (Thin Film Transistor) LCD.

This is the interface board that talks to the Logic board and the LCD panel to produce pictures on the screen. White/gray glowing screen when it fails or not getting the voltage from the logic board (the 5 or 12vdc is supplied by switched transistor on the logic board). Notes: T-CON board is mounted under the metal cover shield.

Common failures:

Scrambled pictures, Lines, multiple pictures, color smears/blotches, rolling pictures after warm up.

Blown surface-mounted fuse.

No pictures, very dark screen almost like there is no backlights.

DIY Blue Ring Tester

5) LCD panel assembly to display pictures. The LCD pixels will block or unblock the backlights from the back of the panel to the front of the panel. This is the most expensive part of the TV, it will be more than the TV is worth.

As you can see, you must have all the above Voltages and signals for the TV to work properly. This may help you narrowing down the bad modules instead of buying the wrong module just to find out later that it did not solve the problem. Hope this will help you out.

Sound problem:

Let verify first to narrow down to where the problem can be. First, check the on-screen sound set up menu to make sure the speakers are not set to OFF. If the setting is OK, then attach the powered PC

speakers to the Audio Line out RCA jacks to see if you can get the sound there, if you do, then the

problem can be in the power amp circuits, if you do not get the sound at RCA jacks, then the problem can be in the sound processor circuit.

To get the sound repair, it can be from $150 and up, so if you can put up with using the good set of Powered PC speakers which actually give better sound than the tiny speakers inside the TV, I would keep using it that way, you may want to find out if the on-screen sound setup will allow you to set the audio line out to be VARIABLE which means the sound output feeding the PC speakers can be varied using the TV remote control, then all you have to do is to set the PC volume to about half way up and set the TV volume to whatever you want.

Troubleshooting LCD flat panel TV.

This is the basic guide that can be applied to most LCD flat panel TV.

First, try unplugging it from the outlet for about an hour to see if the TV will reset itself since the minute the TV is plugged into the wall, the power supply and processor will be running 24/7 and the EPROM can get corrupted by spikes and surges. Try using good quality surge suppressor to see if it will help if it happen often.

Look for burnt brown hot spots on the circuit boards, capacitors with leaking/bulging top or seals. Loose wires and connectors. Blown fuses.

Notes: We are dealing with high voltage that can kill you! so if you are not sure what you are doing, please have it fixed by the pro that has proper tools and safety equipment. Try to use GFI

outlet and isolation transformer when work around the TV set and DO NOT DEFEAT THE GROUND

PIN OF THE OUTLET/POWER CORD.

Background on LCD TV: http://en.wikipedia.org/wiki/LCD_television

1) The power supply module (There are 4 regulated output voltages:- Standby 5vdc, switched

5vdc, 12~16vdc, and 24vdc).

The power supply converts the 120/230vac 50/60Hz into DC, then the high frequency (50~100kHz)

switching circuits convert it back to AC but at high frequency which allows the power supply to use

smaller and much lighter weight transformers (Ferrite core instead of the heavy iron core), then this high

frequency AC voltage is fed to the rectifier Diodes to get the DC output and filtered by DC filter capacitors

that must have low ESR (Equivalent Series Resistance) if general purpose electrolytic caps are used, they

will fail within a year or less due to high ESR.

The power supply has Standby 5vdc (5VSB, this is a MUST have before anything else will work,

when this voltage is not present, there will be no any indicator light on the front panel) which is

always on the minute the TV is plugged into the AC outlet, so it is on 24/7 and that is why the power

supply will fail even though you may use the TV not very often. It will see all the voltage spikes and

surges 24/7.

This 5vdc is used to power the Processor and the Infrared remote receiver module which will be waiting

for the command from the remote control or from the power switch, when the Power on command is

received, the Processor will send the turn-on signal (3.3~5vdc) to the power supply module (PSON pin) to the switch on the main 5vdc for the rest of the logic and Tuner circuits, 12~16vdc for the sound

amplifiers (mostly Class D amplifier for efficiency and small size) and for the T-CON board (interface

board between the LCD panel and the Logic board), and 24vdc for the Backlights inverter board (if there is no 24vdc then no backlight).

Common failures:

Blown main AC fuse due to shorted out Diodes, transistors.

Bad capacitors leaking or bulging tops: http://en.wikipedia.org/wiki/Capacitor_plague

Shorted Diodes, transistors in the DC output side.

Testing the power supply output with dummy load:

24vdc testing: Disconnect the wires that go to the inverter board first. You can use two #1157 (using

both Lo & Hi filaments by paralleling them at the base) car light bulbs connected in series so they can

handle the 24vdc, this will put light load (about 70w) on the 24vdc output, the voltage out should be

steady at 24vdc (+/-2v), if not, the power supply has regulation problem.

12vdc testing: disconnect the 12vdc TV load from the power supply board and attach one #1157 (using just the Hi filament), the 12vdc output should stay at 12v (+/-1v), if not, the power supply has a regulation problem.

You should see the lamps go on when the TV power switch is ON and go OFF when the TV is powered

OFF.

2) Main Logic board (It has Processor, Tuner, Sound Processor, Sources selector, Power

amplifiers for speakers, interface port to the T-CON board for pictures).

This logic board sends out the turn on signals (3.3~5vdc) to turn on the rest of the Power supply module

(Switched main 5vdc, 12~16vdc, and 24vdc), Inverter backlight ON (if no backlight on command then

there are no backlights),

Logic board supplies 5 or 12vdc to T-CON board B+ pin through switched transistor if T-CON board does

not get the voltage from the logic board, you will get a white/gray glowing screen without pictures.

Backlights Dimming (PWM) control signal.

3) Back lights Inverter board. Its job is to provide the drive voltage for the CCFL (Cold Cathode

Fluorescent Lamp) to give white light for the screen.

This board is fed by the switched 24vdc (VBL) from the power supply module, it also gets the Back lights

on (BL on) control signal and the Dimming (Dim/PWM/) signal from the logic board. So for it to work, it needs 24vdc and the BL_ON signal.

Common failures:

Blown surface mounted fuses due to shorted transistors/ICs, Transformers.

Bad capacitors.

4) The T-CON (Timing Control or LCD controller) board (on the LCD panel assembly). It transfers the universal image signal of TTL and LVDS signal to specific TFT (Thin Film Transistor) LCD.

This is the interface board that talks to the Logic board and the LCD panel to produce pictures on the screen. White/gray glowing screen when it fails or not getting the voltage from the logic board (the 5 or 12vdc is supplied by switched transistor on the logic board). Notes: T-CON board is mounted under the metal cover shield.

Common failures:

Scrambled pictures, Lines, multiple pictures, color smears/blotches, rolling pictures after warm up.

Blown surface-mounted fuse.

No pictures, very dark screen almost like there is no backlights.

DIY Blue Ring Tester

5) LCD panel assembly to display pictures. The LCD pixels will block or unblock the backlights from the back of the panel to the front of the panel. This is the most expensive part of the TV, it will be more than the TV is worth.

As you can see, you must have all the above Voltages and signals for the TV to work properly. This may help you narrowing down the bad modules instead of buying the wrong module just to find out later that it did not solve the problem. Hope this will help you out.

Sound problem:

Let verify first to narrow down to where the problem can be. First, check the on-screen sound set up menu to make sure the speakers are not set to OFF. If the setting is OK, then attach the powered PC

speakers to the Audio Line out RCA jacks to see if you can get the sound there, if you do, then the

problem can be in the power amp circuits, if you do not get the sound at RCA jacks, then the problem can be in the sound processor circuit.

To get the sound repair, it can be from $150 and up, so if you can put up with using the good set of Powered PC speakers which actually give better sound than the tiny speakers inside the TV, I would keep using it that way, you may want to find out if the on-screen sound setup will allow you to set the audio line out to be VARIABLE which means the sound output feeding the PC speakers can be varied using the TV remote control, then all you have to do is to set the PC volume to about half way up and set the TV volume to whatever you want.

Subscribe to:

Posts (Atom)